DEVELOP

DELIVER

Fabric Technology

Pearl Washed Cotton: Our most expensive, most unique and exclusive fabric that we have developed as “Pearl Washed Cotton”. We use “Pearl” because the fabric ends up having a very smooth and clean surface, it is very soft and lustrous that holds it’s color wash after wash and has minimal shrinkage and minimal torque. Like a Pearl this fabric is very elegant and exclusive.

Fabric begins with selecting best cotton available, then we take the yarns and apply the first wash to help clean the yarn. Once the fabric has been knit it then goes into a another wash. that includes a finish that we have exclusively developed with Clariant Corporation out of India.

After the 1st wash we then dye the fabric. We then let this fabric sit for a week so that it has time to relax and stay in it’s normal state without any tension. “Pearl Washed” process gives the fabric on the finished garments the ultimate in performance, softness and color.

Garment Dye Program

Garment dyeing is the process of dyeing fully fashioned garments (such as pants, pullovers, t-shirts, jeans, sweaters, dresses, bathrobes, casual jackets, shirts, skirts, hosieries) subsequent to manufacturing, as opposed to the conventional method of manufacturing garments from pre-dyed fabrics. Most garments are made of cotton knit goods and/or cotton woven fabrics.

Although several other fabrics can be found in the whole or in part such as wool, nylon, silk, acrylic, polyester and others. Due to cost savings and fashion trends, garment dyeing has been gaining importance and popularity in the recent years and will continue to do so in the future.

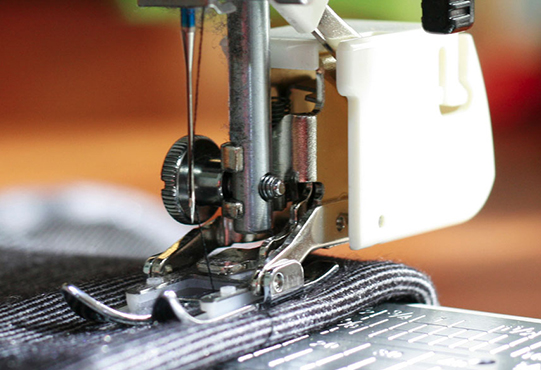

Our Factory

Oxford Apparel established in the year 1998, we have customers across the world with a current supply of more than 60,000 knitted garments per month.100% vertically integrated textile major has been at the forefront of quality and innovations since its inception a decade ago. We have handled, out sourced overseas projects, with cutting edge technologies & quality treatment, which were welcomed & appreciated by our customers around USA, Europe Countries, Australia and south Africa, Oxford creates a one to one relationship with the buyers.

We are having adequate number of experienced employees to make a fabric for a good garment based on the customer need. Due to our cutting edge technologies and expert employees, we reduced the wastage, so that it’s possible for us to manufacture the garment at affordable cost.

GBH Holdings. Has the expertise to design the optimal fabrics and combine the innovative fabrics with superior apparel design. We have the factory capacity to manufacture 130,000+ units per month.

What Makes us Different

We are committed to provide consistent levels of high quality services to our clients. We ensure on-time delivery with the highest quality that will meet and exceed our customer expectations. We clearly understand changing customer needs and strive to redefine Technology and Innovation.

From the Home of the wealthy resourceful land GBH Holdings tends to be more resourceful to make our routines very busy, Active and inspiring to the people, who don’t want to miss the advent in every second,Obviously you do by wearing us “WE DON’T MAKE EXCUSES, WE MAKE RESULTS”.

This story is about GBH Holdings – the company which is responsible in fulfilling the needs of “HIGH END SPORTS FASHION BRANDS IN US”, has a re-search from their regular activities and re-invented with a new technology for the people with the most advent with no excuses in spoiling out Mother Nature’s health. “First impression is the best”- a truthful saying, having this in our mind we are working with experienced technicians with the STATE OF ART TECHNOLOGY in garment making. Our products give a good comfort and a graceful hug and to go along with the twist and turns of a wearer.