Processing

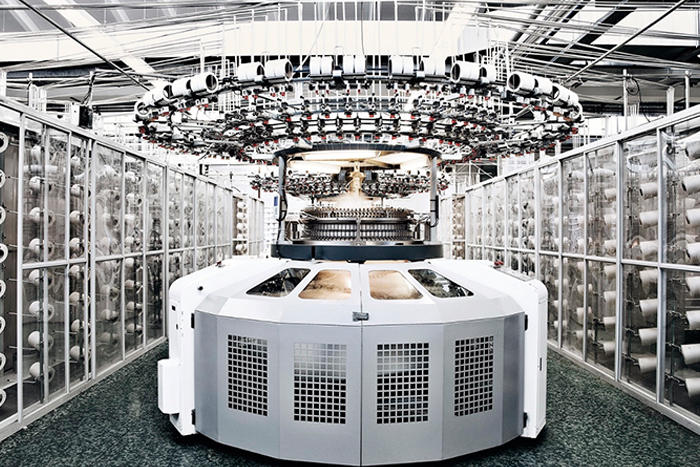

Our most sophisticated and modern knitting machines all, imported from abroad are capable of providing the most intricate knitting designs / patterns required to suit the changing trends. All machines have Lycra attachment.

Soft FLow Dye

Our dyeing unit is situated in the outskirts of Tirupur and has the facility of doing sample programs and bulk production having automatic lab dip machines and manual lab dip machines besides water effluent treatment plants all these facilities enable us to add new customers.

Compacting

Compacting Machine is Imported from Germany. It maintains the shrinkage control to below 5% meeting all International Standards.

- Band Knife Cutting Machine

- Advance band knife Machine

- Embroidery

Printing

Chest Printing Machines with 10,000 pieces a day. To print upto 12 colours chest printing with Non PVC also.

All type of Prints Like Plastisol prints, Foil prints, Flock prints, High density prints, Gel prints, Matt prints are made in house which gives the Value addition in the garments.

Stitching

We have the privilege of providing the widest range of Stitching styles, to suit any buyer around the globe. We possess 50 sewing machines all are sophisticated and most Modern machines imported from Japan.

Ironing

Steam Ironing is the used remove wrinkles from fabric. Ironing works by loosening the bonds between the long-chain polymer molecules in the fibers of the material. While the molecules are hot, the fibers are straightened by the weight of the iron, and they hold their new shape as they cool.

Quality Control

Quality Controller (QC) is responsible for the quality of the product. One or more number of persons will involve in inspecting the quality of a garment in different stages of production. Once the QC approves, the garment will be sent to packing section.

Packing

Final process is packing the garment based on the buyer needs. If QC approves then all fine finished products will go for packing.Garments are packed neatly in the designated packs and placed inside the carton or hanger racks and ready for dispatch.